Home > PVSTOP Products – Solar Safety Solutions and Training > Portable Pressure Vessel – Handheld Solar Safety Application

Professional-Grade Solar Safety at Your Fingertips

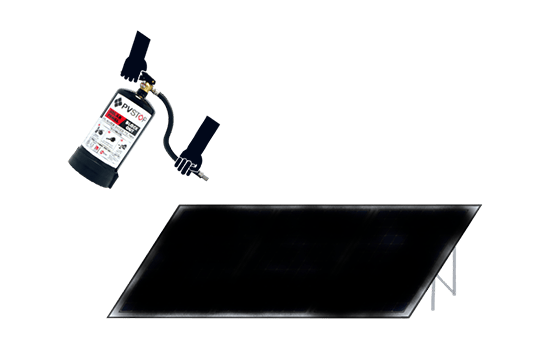

PVSTOP is a temporary peelable protective coating that when applied to the surface of solar PV panels is designed to de-energise (switch off) the power produced by the solar PV system. Applied in a liquid state, the coating dries to form a protective barrier that will last for up to 12 months. DO NOT USE ON ACRYLIC SURFACES.

Water Based Polymer

Black

The compound is non-toxic and non-conductive. When applied to the surface of solar panels, the coating is non-flammable in both its wet and dry states. The dry coating waste may be disposed of in general waste. Please see separate Material Safety Data Sheet (MSDS) for further Health and Safety Information.

Shelf life, from date of manufacture is 36 months when stored in an approved fire extinguisher type pressure vessel and 24 months when stored in an Intermediate Bulk Container (IBC). Store at temperatures between 5°C – 60°C. DO NOT ALLOW LIQUID TO FREEZE.

Solar PV Panels

We do not compromise on performance or environmental responsibility, ensuring both safety and peace of mind.

Underwriters Laboratories, UL8 listed 2.5 Gallon, Portable Extinguisher Vessel

Australian & New Zealand Standards, AS/NZS 1841.2:2007 Certified 9 Litre & 4.5 Litre, Portable Extinguisher Vessels

UKCA and CE Certified (EN 3-8), 9 Litre & 4.5 Litre, Portable Pressure Vessels

PVStop is the only product that quickly and safely isolates the power produced by solar PV systems at the source - the solar panels themselves.

The coating will extinguish a Class A fire in its wet state.

PVSTOP dries into a heat resistant, protective film.

The spray insulates against electrocution risk.

Eliminates PV system electrical arcs as soon as the coating is applied to solar panels.

Encases toxic material release from burning solar panels, reducing inhalation and environmental damage.

Dries into a shock-absorbing film that shields solar panels.

5°C – 60°C (41°F – 140°F) DO NOT ALLOW LIQUID TO FREEZE, this will void the product warranty.

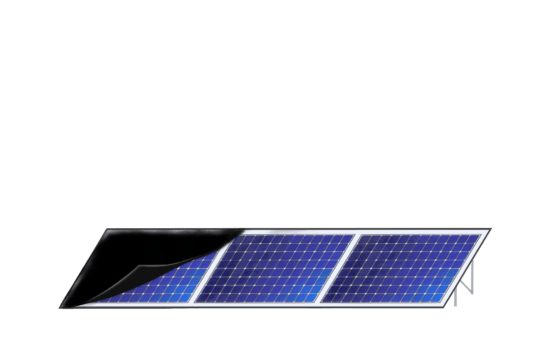

PVSTOP should be applied differently depending on your panel orientation and type. Select one of the options below to see the relevant application process.

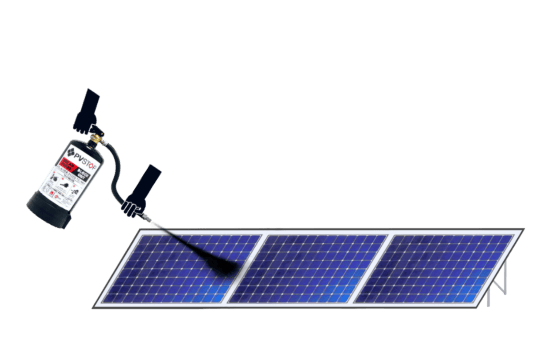

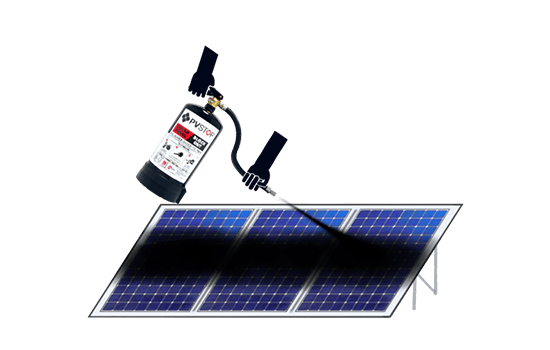

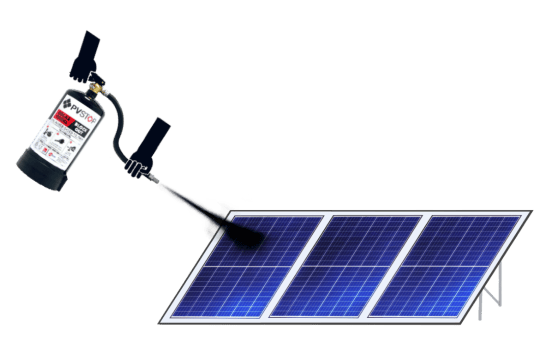

Remove the safety pin, aim hose nozzle at solar panels.

Squeeze the handle to apply PVSTOP.

Apply evenly, similar to painting a wall. Avoid over-application as it slows drying time and reduces coverage area.

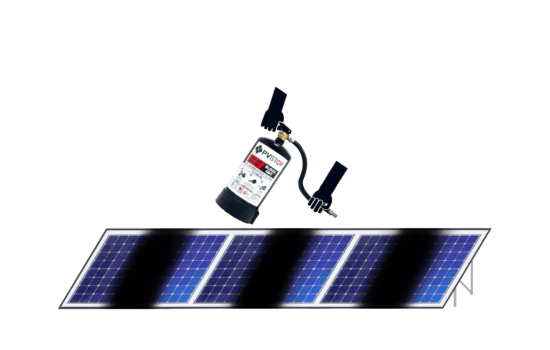

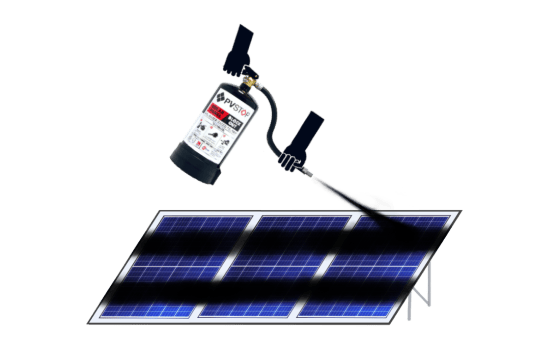

Spray PVSTOP across the centre of the PV Panels, covering at least 40% to stop power generation.

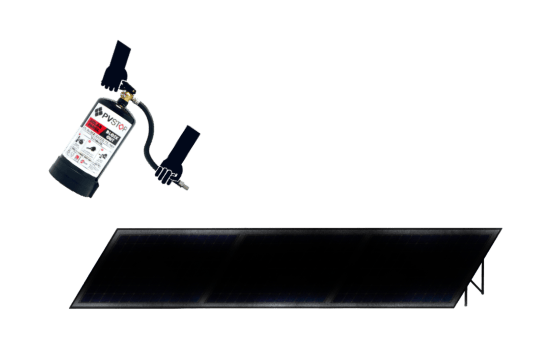

For maximum safety and easy removal, coat all panels completely or until the canister is empty.

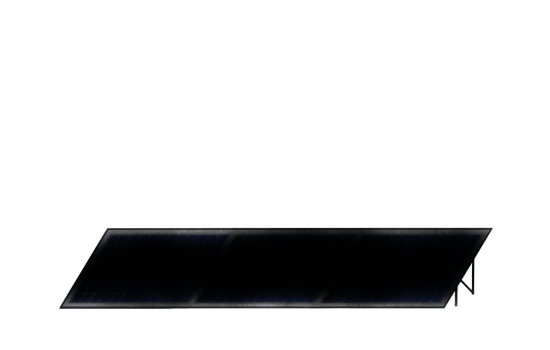

At 25ºC (77ºF), the coating is "tack dry" in 5 minutes and "tack free" in 120 minutes.

When safe, peel PVSTOP off solar panels without damage. Dispose of the environmentally friendly film as general waste.

An electrical Technician must inspect before safely reactivating the PV system.

Remove the safety pin, aim hose nozzle at solar panels.

Squeeze the handle to apply PVSTOP.

Apply evenly, similar to painting a wall. Avoid over-application as it slows drying time and reduces coverage area.

Spray PVSTOP across the centre of the PV Panels, covering at least 40% to stop power generation.

For maximum safety and easy removal, coat all panels completely or until the canister is empty.

At 25ºC (77ºF), the coating is "tack dry" in 5 minutes and "tack free" in 120 minutes.

When safe, peel PVSTOP off solar panels without damage. Dispose of the environmentally friendly film as general waste.

An electrical Technician must inspect before safely reactivating the PV system.

Remove the safety pin, aim hose nozzle at solar panels.

Squeeze the handle to apply PVSTOP.

Apply evenly, similar to painting a wall. Avoid over-application as it slows drying time and reduces coverage area.

Spray PVSTOP across the centre of the PV Panels, covering at least 40% to stop power generation.

For maximum safety and easy removal, coat all panels completely or until the canister is empty.

At 25ºC (77ºF), the coating is "tack dry" in 5 minutes and "tack free" in 120 minutes.

When safe, peel PVSTOP off solar panels without damage. Dispose of the environmentally friendly film as general waste.

An electrical Technician must inspect before safely reactivating the PV system.

Everything you need to know about PVSTOP and when to use it.

We do not compromise on performance or environmental responsibility, ensuring both safety and peace of mind.

PVSTOP dries into a waterproof, protective film. At an ambient temperature of 25°C (77°F), the coating becomes 'tack dry' in approximately 5 minutes and 'tack free' within 120 minutes.

PVSTOP safeguards solar PV systems without causing damage. If an incident is not PV-system-related, an accredited technician can service and restore the system to full operational capacity.

The dry film is removable by hand or high-pressure water spray from most non-porous surfaces, but may become brittle in freezing conditions.

The Portable Pressure Vessel has a delivery range of up to 10 meters (30ft), depending on wind conditions.

The 9L/2.5Gal PVSTOP Pressure Vessel has a practical coverage rate of approximately 34m² (360 sq ft), depending on the distance from the target, wind conditions, and the operator's skill level.

PVSTOP Portable Pressure Vessels are designed for single use and are not meant to be refilled.

Designed to withstand weather exposure for up to 12 months.

Clean PVSTOP-coated equipment with water immediately after use. Note: the coating CANNOT BE REMOVED from woven materials, such as personal protective equipment, once tack-free.

PVSTOP is a temporary peelable protective coating that, when sprayed onto solar panels, acts like a ‘liquid tarpaulin’ to block light and de-energize the solar PV system within seconds. It’s designed to isolate the power produced by solar panel systems without damaging them.

PVSTOP ‘switches off’ a solar panel system in a matter of seconds once applied.

A PVSTOP canister can spray up to 10 meters (30 feet) in ideal conditions.

No, only 40% coverage of each solar panel is required to reduce DC electricity to safe levels. However, 100% coverage is recommended as best practice.

Yes, PVSTOP works in all weather conditions, including rain and on wet solar panels.

Once dry, PVSTOP can be easily peeled off by hand or removed with a high-pressure water spray without damaging the solar panels.

PVSTOP is designed to be left on a solar PV system for up to 12 months, or until the PV system is ready to be re-activated.

Yes, PVSTOP is environmentally friendly and non-toxic. It has been tested and approved by various environmental agencies and does not contain PFAS, PFOS, or PFOA chemicals.

PVSTOP holds several certifications, including ISO 14034:2016 Environmental Management – ETV, European Commission Environmental Technology Verification, and TUV Rheinland Middle East Product Conformity Certificate.

Whether you're interested in our innovative Handheld Vessel, cutting-edge Drone Delivery System, comprehensive Online eLearning Program, or immersive VR Training, we're here to help you find the perfect PVSTOP solution. Have questions about product specifications? Need a customised quote? Want to schedule a demo or training session? Our team of experts is ready to assist you. Please fill out the form, and we'll connect you with a PVSTOP specialist who can provide detailed information, answer your questions, and guide you towards the best solution for your solar safety requirements.

"*" indicates required fields

A 'liquid blanket' that shuts down solar panels in seconds and eliminates the risk of high voltage DC electrocution.